“Join xAI if the idea of mass drivers on the Moon appeals to you,” CEO Elon Musk proclaimed yesterday following a restructuring that saw a stream of former executives exit the AI lab. This is an interesting recruitment strategy after the company’s merger with Musk’s rocket maker, SpaceX, and the combined company’s anticipated IPO. You

3D Printing and AI: Generating Designs with Machine Learning Algorithms

Home / Technology / 3D Printing and AI: Generating Designs with Machine Learning Algorithms

—

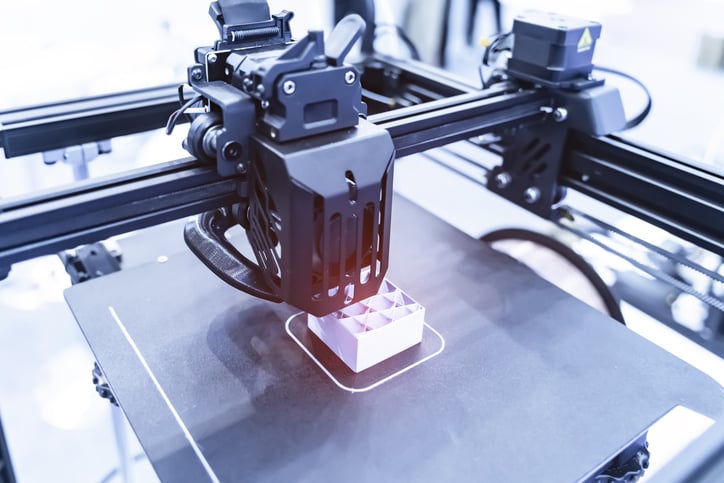

Technology enables the creation of complex objects, such as 3D printing combined with AI, especially machine learning, revolutionising manufacturing by building layer by layer. It progresses industries by making design smarter and more intuitive, with AI offering early optimised suggestions. This is the promise we’re exploring here.

3D printing creates objects from digital models by layering material. AI improves these models using data insights, while machine learning predicts outcomes and optimises designs from large datasets. This enables faster prototyping, reduces waste, and supports sustainability. Algorithms automate design processes, helping designers find solutions that might be hard to identify manually.

How Machine Learning Algorithms Work in Design Generation

Let’s break down the core of this integration. Machine learning algorithms analyse historical data from previous prints to generate new designs. For instance, generative design tools use these algorithms to explore thousands of possibilities within constraints such as material strength or weight limits. You input your requirements, and the system outputs optimised options. This process relies on techniques inspired by biological neural structures that model complex patterns in data to process information.

Machine Learning Techniques in Practice

In practice, CNNs help interpret image-based inputs such as scans or sketches, supporting the reconstruction of printable 3D geometries. Reinforcement learning takes it a step further by allowing the algorithm to learn through trial and error, adjusting designs iteratively within simulated environments based on feedback.

Supervised learning, where the model trains on labelled data, helps predict potential defects early in the design phase. These methods ensure the final design not only works well but also uses materials and production processes efficiently.

Real-World Application and Benefits

Consider how this applies to everyday challenges. If you’re designing a part for machinery, machine learning can simulate stress tests virtually, suggesting modifications before any physical printing occurs. This predictive capability reduces errors and enhances reliability. Where industries like mining and aerospace demand precision, such tools are invaluable. These algorithms democratise advanced design, making it accessible even to smaller teams without extensive resources.

Benefits of AI-Driven Design in 3D Printing

Why should you care about this technology? The benefits are clear and impactful. First, it significantly reduces development time. Traditional design might involve multiple prototypes, but AI generates optimised versions quickly, often significantly reducing the number of design iterations. This efficiency translates into cost savings, as less material is wasted and fewer hours are spent on revisions.

Enhanced Sustainability and Resource Efficiency

Moreover, AI promotes sustainability, a priority for many. By optimising designs for minimal material use, machine learning helps create lighter yet stronger components. Imagine producing parts that perform better with fewer resources; it’s a win for both the business and the environment.

Improved Quality Control and Reliability

Quality control improves, too, with algorithms detecting anomalies during the design stage, ensuring the printed object meets high standards.

Greater Innovation and Accessibility for Designers

Engagement with users is another plus. Designers can iterate based on real-world data, leading to more innovative outcomes. For those in creative fields, this means exploring designs that were once too complex to attempt manually. The compassionate side is that it levels the playing field, allowing emerging talent to compete globally without requiring massive investments.

Professional Support for Turning Designs into Reality

If you’re in the midst of a project and need professional support, a reliable 3D printing service in Sydney like CAD Deziners could help bring your AI-generated designs to life. We offer expertise that seamlessly complements these advanced tools.

Applications Across Various Industries

Now, let’s look at where this technology shines in real-world scenarios. In aerospace, machine learning enables the development of lightweight components that withstand extreme conditions. Companies use topology optimisation to create structures with reduced weight, improving aircraft fuel efficiency, a critical factor given the vast distances.

The biomedical field benefits immensely as well. AI algorithms process patient data to design custom implants or prosthetics that fit perfectly. By analysing scans, machine learning helps model how designs may interact with the body, supporting clinically validated, patient-specific solutions. This personalised approach is transforming healthcare, making treatments more effective and patient-centred.

The automotive industry uses this approach for parts that improve vehicle performance. Generative design produces complex shapes that are difficult or inefficient to manufacture using traditional methods, leading to stronger, lighter vehicles. As electric vehicles become more popular, AI helps optimise battery components for greater efficiency.

Even in construction and consumer goods, the impact is evident. Machine learning optimises material usage and structural design to support sustainability. These applications demonstrate the technology’s versatility, adapting across diverse sectors while maintaining a focus on precision and innovation.

Challenges and Considerations in Implementation

Of course, no technology is without hurdles. One key challenge is data quality; machine learning thrives on accurate, extensive datasets, but gathering this in 3D printing can be time-consuming. Inaccurate data leads to flawed designs, so ensuring reliable inputs is essential.

Integration with existing systems poses another issue. Not all 3D printers or software are AI-ready, requiring updates or new investments. For businesses, this means planning carefully to avoid disruptions. Additionally, there’s the learning curve; teams need training to use these tools effectively.

Security concerns arise, too, as designs involve sensitive data. Protecting intellectual property in an AI-driven environment is crucial. Despite these challenges, the professional community approaches them with care, developing standards to mitigate risks. It’s about balancing innovation with practicality to ensure safe adoption.

Future Trends in AI and 3D Printing

Looking ahead, what can we expect? Trends point towards even deeper integration, with AI supporting greater automation across the workflow, from design through production, with human oversight. Predictive maintenance, where algorithms forecast printer issues, will minimise downtime. Autonomous systems could independently select materials and parameters, streamlining operations.

Advancements in deep learning will enable more sophisticated simulations that incorporate real-time environmental factors. This could mean designs increasingly optimised for specific environmental conditions, such as heat-resistant applications.

Hybrid models combining physics-based simulations with machine learning promise greater accuracy. As computational power grows, these trends will accelerate, making AI indispensable in 3D printing. The future looks promising, with ongoing research paving the way for breakthroughs.

Final Thoughts

The combination of 3D printing and AI, particularly through machine learning for design, has significant transformative potential. It enables us to innovate and produce efficiently and sustainably. As many people adopt this technology, it unlocks new opportunities in manufacturing and other fields.

For anyone exploring options for 3D printing in Melbourne, CAD Deziners offers a strong foundation to turn ideas into reality. Thoughtfully embracing this fusion will drive progress for years to come!

—

This content is brought to you by Sajid Saeed

iStockPhoto