Real-world test of Apple's latest implementation of Mac cluster computing proves it can help AI researchers work using massive models, thanks to pooling memory resources over Thunderbolt 5. In November, Apple teased inbound features in macOS Tahoe 26.2 that stands to considerably change how AI researchers perform machine learning processing. At the time, the headline

A

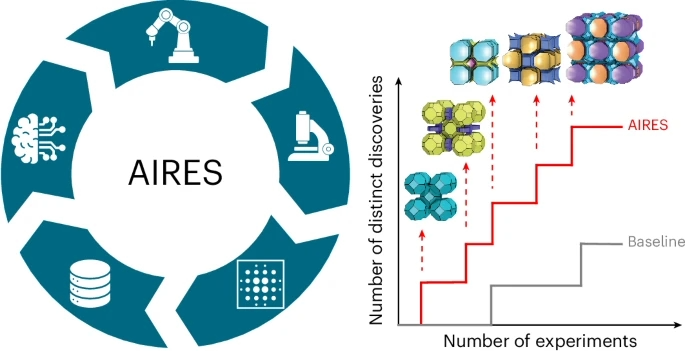

A multi-institution research team has unveiled AIRES (Algorithmic Iterative Reticular Synthesis), a powerful AI-driven platform designed to dramatically speed up the discovery of new crystalline materials. Published recently in Nature Synthesis, the work shows how artificial intelligence and automated experiments can replace much of the slow, trial-and-error approach that has traditionally defined materials discovery.

AIRES combines robotics, imaging tools, X-ray crystallography, and an AI system that learns which experiments are most promising, not just for making one material, but for uncovering as many different structures as possible. Instead of relying on intuition, the platform turns reticular chemistry into a structured, data-guided exploration, speeding up the discovery of new crystals.

At the heart of the study are crystalline materials—particularly reticular materials, i.e., highly ordered, crystal-like structures built by connecting molecular building blocks into repeating networks, much like assembling a scaffold from LEGO® pieces. These materials, which include metal-organic frameworks (MOFs), are promising for applications such as carbon capture, water harvesting, catalysis, and energy storage. However, discovering new versions of these materials has long been difficult because even small changes in chemistry or experimental conditions can determine whether a crystal forms at all.

Zichao Rong, a senior graduate student in the Yaghi Lab and lead author of the AIRES study.

AIRES was developed through a collaboration between researchers at UC Berkeley, VinUniversity, and Monash University, reflecting more than three years of sustained international collaboration. The team used AIRES to explore a class of porous materials called zeolitic imidazolate frameworks (ZIFs), structures known for their chemical versatility but also for being especially hard to synthesize reliably.

Examples of reaction outcomes used in AIRES, including ZIF single crystals (blue frame), paired with their ball-and-stick structural representations.

Rather than relying on intuition or manual guesswork, AIRES runs many experiments quickly, analyzes the results, and uses machine learning to decide which experiments to try next. When tested in a challenging and largely unexplored chemical space, the system doubled the crystal discovery rate compared to random experimentation, successfully converting 10 new molecular building blocks into 7 distinct crystalline network structures.

“Predicting whether a complex chemical reaction will succeed is still extremely difficult with traditional simulations,” said Zichao Rong, a fifth-year graduate student in the Yaghi Lab and lead author of the study. “Instead, we built a system that learns directly from real experimental outcomes. AIRES collects high-quality data from automated synthesis and uses crystal structure measurements to train the model, allowing it to recognize patterns and guide future experiments much more efficiently.”

The AIRES experimental platform generates a large volume of reaction data and uses automated optical microscopy and a crystal recognition deep learning model to rapidly identify promising reaction outcomes for subsequent single-crystal XRD verification.

The AIRES experimental platform generates a large volume of reaction data and uses automated optical microscopy and a crystal recognition deep learning model to rapidly identify promising reaction outcomes for subsequent single-crystal XRD verification.

Importantly, the structures discovered by AIRES serve as what the team calls “structural anchors”, fully verified materials that provide a reliable foundation for further study. These anchors can be used for computer modeling, scale-up synthesis, and future AI systems designed to predict material properties or generate entirely new materials.

“In the bigger picture, AIRES represents an important step toward the digital future of chemistry,” said Omar M. Yaghi, BIDMaP Co-Director and Chief Scientist. “By linking experimental data with machine learning, AIRES can integrate seamlessly with other AI tools for materials design, optimization, and real-world deployment.”

The single-crystal XRD workflow provided the verified structural anchors that make the AIRES dataset uniquely reliable.

BIDMaP leadership emphasized that the work exemplifies the institute’s core mission of uniting artificial intelligence with experimental science.

“AIRES shows how AI and laboratory automation can work together to make materials discovery faster, more systematic, and more reliable,” said Sarah Jones, Executive Director of BIDMaP. “This is exactly the kind of interdisciplinary innovation BIDMaP was created to enable.”

“This project demonstrates the power of tight feedback loops between computation, robotics, and chemical synthesis,” added Christian Borgs, BIDMaP Faculty Director. “Platforms like AIRES point toward a future where discovering new materials is not only faster, but scalable in ways that were previously impossible.”

By transforming materials discovery from an art guided by intuition into a data-driven, iterative process, AIRES marks a significant advance toward creating the next generation of materials needed to address pressing global challenges, from clean energy to climate resilience.