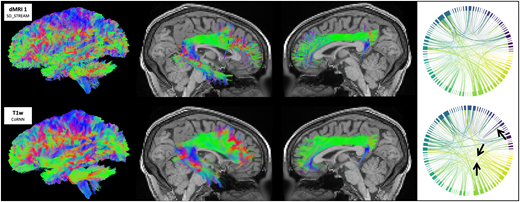

Introduction Deep learning is an advanced machine learning technique based on artificial neural networks inspired by a human brain, especially featuring the capability to automatically extract complex patterns of data by multi-layer neural networks [1,2]. The neural network consists of input, hidden, and output layers. Unlike conventional machine learning algorithms, deep learning architectures have multiple

News: Case studies: Effective use of Machine learning in manufacturing.

POSTED 07/25/2025

Case studies: Effective use of Machine learning in manufacturing.

Production has gone through a revolutionary phase fuelled by Industry 4.0. The combination of progress in sensors, connectivity and data analytics has changed factories and now can distill useful patterns out of the torrents of data. Machine learning is a subdivision of artificial intelligence that takes a central role in enhancing quality control, predictive maintenance, process optimization, energy efficiency, inventory management, and design innovation. So, how are the top companies using ML to address challenging tasks and extract genuine business value? Kindly take a look by reading this article.

1. Quality Control & Defect Detection

a). BMW: Computer Vision based Visual QC BMW applies computer vision with machine learning to examine automotive parts regarding defects. Using convolutional neural networks to process high-resolution images has allowed BMW to decrease manufacturing flaws by around 40 percent, a major improvement in product dependability and a tiny fraction of re-work.

b). Vitra Karo: Fault Diagnosis in Kilns

Real-time defect detection in kilns at 1,500 °C Turkish tile producer Vitra Karo deployed ML-accelerated cameras and GPUs in real-time defect detection in kilns at 1,500 °C.

The innovation reduced the scrap rate by more than 50 percent, proving the functionality of ML even in extreme conditions .

c). Philips / Streaming Active Learning

Philips used streaming machine learning and active learning to automatically perform visual inspection. Their system saved approximately 15% manual labeling work while preserving the efficiency and accelerating inspection work by up to 40%.

2. Predictive Maintenance & Equipment Reliability

a). ArcelorMittal: ML in Action – Steel Mill Uptime ArcelorMittal invested in sensors throughout its steel apparatus to check the temperature, vibration, and performance. By using ML models to predict failures in advance, unplanned downtime was decreased by 20% and maintenance costs were decreased by 15%, and reactive maintenance became proactive.

b) ZF Friedrichshafen: Honing of Gears Maintenance

ZF applies vibration sensors and ML at its Saarbrücken facility to forecast the failures of gear honing rings with a 99% accuracy rate. This predictive maintenance system reduces the unexpected down time and improves the equipment efficiency.

c) General Electric Power Plants: Digital Twins Maintenance

General Electric has installed its own Predix solution that uses digital twins and ML to monitor equipment. The payoff: Unplanned downtime was reduced by 40%, maintenance expenditures by 20%, and operating efficiency increased by 10%.

3. Supply chain optimization & Inventory Management

a) Siemens: Time-Series Forecasting of Demand Demand Forecasting Time-Series

Siemens uses ML and time-series analysis in order to enhance inventory optimization and demand forecasting. Their system has reduced supply chain expenses by a quarter and has enhanced the logistics and stock maintenance .

b) Caterpillar: Spare Parts Prediction

Caterpillar relies on ML to forecast the demand of spare-parts. This forecasting category reduced overstocking by 20%, cutting stock holding costs and improving maintenance preparedness.

c) Ocado: Warehouse Management Software

Ocado applies ML to dynamic product placement in its automated warehouses. Fast-moving products are laid closer to picking areas which enhances speed of retrieval and efficiency of a warehouse.

4. Process Optimization & Digital Twins

a) SAS & Georgia‑Pacific: Modeling Plant Processes

SAS also developed digital twins in collaboration with Epic Games to model the manufacturing settings at Georgia‑Pacific. The model also provides the optimum traffic path of workers and autonomous vehicles that increase safety and efficiency in plant floors.

b) Airbus: Generative Design and Simulation Airbus is using ML to come up with design options of aircraft parts. It speeds up design cycles by thirty-five percent with the ability to cut material waste and escalate innovation.

c) Digital Twin in Power Operations General Electric Power

General Electric is applying digital twins to model the performance of power plants, optimize fuel consumption and predict failures–with the result being higher efficiency and lower costs.

5. Energy Management & Sustainability

a) Toyota: Optimization of Plant Energy Toyota deployed ML systems to observe the energy usage on a plant level. This project has saved 20% of the energy expenditure and has contributed greatly towards sustainability.

b). Energy Forecasting Models using IIoT.

The ML models such as autoregressive and deep neural networks are employed by the factories to make accurate predictions of the energy requirements. The outcome: reduced expenses, wastage and improved planning.

6. Generative Design Product Design

a) Airbus: improved Aircraft Design implements ML in its design process, Airbus is examining thousands of variations of components, leading to quicker, lighter, and more efficient designs.

b). Rolls -Royce: Jet Engine Development

Certified System Integrator Program

Set Yourself at the Forefront of the Global Vision Market

Vision system integrators certified by A3 are acknowledged globally throughout the industry as an elite group of accomplished, highly skilled and trusted professionals. You’ll be able to leverage your certification to enhance your competitiveness and expand your opportunities.

Vision system integrators certified by A3 are acknowledged globally throughout the industry as an elite group of accomplished, highly skilled and trusted professionals. You’ll be able to leverage your certification to enhance your competitiveness and expand your opportunities.

GET CERTIFIED

Rolls‑Royce applies data-driven simulation and ML to engine design, which uncovers weaknesses and strengths at an early stage, therefore, enhancing quality and cutting costs.

7. Intelligent Inventory & Warehouse Intelligence

a) Amazon:ML Inventory Real-Time Inventory placement and logistics Amazon uses ML to maximize inventory placement and logistics, which result in shorter lead times and lower costs of inventory .

8. Additive Manufacturing Materials

a). Physics‑Informed Neural Networks. Physics-informed neural networks (PINNs) provide an approach to thermo- and fluid-dynamic modelling in metal 3D printing, as used by engineers. This data‑based method combines physical prior with learning models to make predictions more accurate using less data.

b). Materials Discovery DeepMind

The GNoME platform developed by DeepMind has found more than 2 million stable crystal structures, of which approximately 71 percent have been confirmed experimentally – opening the era of AI-accelerated materials discovery.

9. Claim Recovery Warranty

a). Heavy Equipment Manufacturer: ML to Recoup Claims Pariveda developed an ML model (AWS SageMaker + Databricks) to detect supplier-at-fault warranty claims. The system identified more than $13 M of unsubmitted claims, and the potential recoveries were approximately $7 M.

10. Automation and Adaptive Manufacturing

a). Industrial Adaptive Machines

The adaptive machines in the factories get the tooling and conveyor flows auto-adjusted, depending on the type of product. Applications are made of customizable bottling, dynamic labeling, and flexible packaging- with ML integrated to become adaptive on the fly.

11. Macro-Level Developments & Strategy Perspective

a). U.S. Industrial AI Forum

Samsung and Siemens executives argued about advanced manufacturing reshoring. Siemens focused on industrial AI and digital twins to detect defects, maintain, and enhance throughput .

b). SAS Innovate 25 Accentuations

SAS presented digital twin simulations of Georgia-Pacific and quantum-hybrid AI models at Procter and Gamble- processing ingredient combinations in 6 hours to 12 minutes.

Key Takeaways: The Importance of These Case Studies

1. Measurable ROI: Documented

The high impact of ML is shown by improvements: defects reduced by 40% to 50%, downtime by 2040%, millions of dollars saved.

2. Cross-Functional Integration: ML cuts across quality, maintenance, energy, logistics, design and finance.

3. Technological Blend: IoT sensors, computer vision, cloud platforms, digital twins, and quantum-hybrid methods are integrated.

4. Cultural & Workforce Transformation: Organisations are focusing on upskilling teams so that they can collaborate with intelligent systems.

5. Newcomers: New entrants such as Vitra Karo, heavy-equipment companies, tank aggregation, and additive manufacturing demonstrate the wide use of ML.

Best Practices when manufacturers use MLSTEPS STRATEGIES

1. Start Small Conduct pilot projects (e.g., camera-based defect inspection, vibration-based maintenance).

2. Data Foundation Labeled samples and quality sensor data take precedence.

3. Cloud + Edge Use clouds such as AWS, azure, SAS Viya or Predix with on-premise inference where necessary.

4. Digital Twins Create simulation environments in which process changes can be tested without interfering with operations.

5. ML + Physics When data is sparse or costly, use hybrid modeling (e.g., PINNs).

6. Pay attention to ROI Measure savings in scrap reduction, downtime, energy, inventory and warrant claims.

7. Governance & Skills Include ethics, compliance and workforce development in the early planning.

The Future of ML in Manufacturing

1). Quantum-Hybrid Models: An increasing number of companies (such as P&G) will adopt quantum-aided ML to solve higher dimensional combinatorial problems.

2). Edge Analytics Proliferation: ML at the production lines will be possible in real-time due to on-device intelligence.

3). Autonomous Adaptive Factories: Smart production systems that have adaptive machines will become a norm.4). Cross-Enterprise Intelligence: ML will also enable end-to-end resilience – predicting demand, planning suppliers and logistics disruption.

5). Sustainability Mandates: ML and materials discovery tools powered by energy will be the hallmark of the green factory of the future.

Conclusion

These case studies reveal the value of machine learning in the manufacturing industry in terms of quality assurance, maintenance, logistics, design, energy management, and financial gain. BMW, GE, Siemens, ZF, Toyota, Caterpillar, Airbus, and other companies are experiencing tangible improvements in efficiency, cost reduction, and the rate of innovation. With pervasive sensors and dropping compute costs, the next generation of AI-powered production will feature self-optimizing equipment, more intelligent supply networks, and morelean operations. The path to success is to begin with limited resources, select pilots that have a substantial impact, adequate data plumbing, and the development of teams that are competent to AI. Machine learning is no longer the nice-to-have innovation of the firms that are eager to gain next-generation competitiveness and resilience, it is a must-have.