Tech Comments (3) Luis Alvarez Adobe (NASDAQ:ADBE) and GitLab (NASDAQ:GTLB) shares slipped in early trading on Tuesday as investment firm Mizuho said the market believes it is seeing a “severe negative impact” from artificial intelligence. “ADBE sits at the intersection of creative software and generative Quick Insights Recommended For You

Scaling Complex Molecular Reactions with Hybrid AI Models – BIOENGINEER.ORG

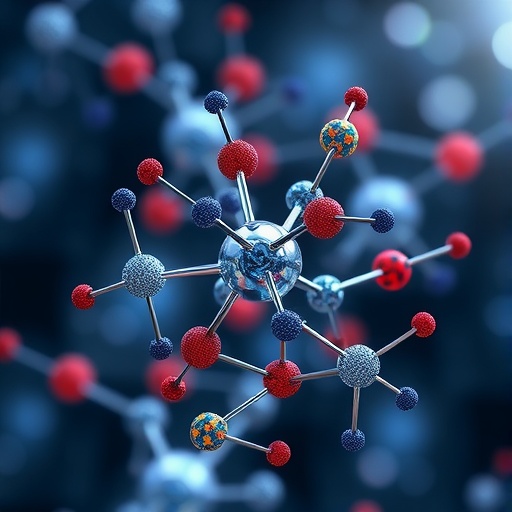

In the ever-evolving domain of chemical reaction engineering and molecular synthesis, scaling up complex molecular reaction systems has long posed a formidable challenge. The recently published work by Chen, Z., Xie, Y., Xu, C., and their colleagues marks a significant milestone in this quest by introducing an innovative hybrid approach that combines mechanistic modeling with deep transfer learning. This breakthrough paves the way for more efficient and predictive scale-up methodologies, potentially revolutionizing how molecular processes are engineered in both academic and industrial settings.

Traditionally, the scale-up of molecular reaction systems relies heavily on purely mechanistic models derived from fundamental chemical kinetics and thermodynamics. While these models are mathematically rigorous and grounded in physical principles, they often struggle to capture the full complexity of real-world reactions, especially when dealing with multiphase systems, competing pathways, and intricate intermediates. The large parameter space and the nonlinearity inherent in such reactions can quickly overburden classical models, resulting in predictions that may lack precision or fail entirely when transitioning from lab scales to production.

Enter deep learning, with its powerful capacity for capturing nonlinear correlations and adaptively modeling complicated datasets without explicit a priori knowledge. The research team embraces this capability by coupling deep learning algorithms with mechanistic insights, forming a hybrid modeling framework. This hybrid approach leverages the interpretability and physicochemical rigor of mechanistic models while harnessing the data-driven adaptability and pattern recognition strength of deep learning. Such synergy is a central theme of modern computational chemistry, aiming to overcome the limitations encountered when either method is used in isolation.

The core innovation lies in the integration of deep transfer learning—a subset of deep learning where knowledge gained in solving one problem is leveraged to accelerate and improve learning in another related context. In molecular reaction scale-up, this means the model trained on data from smaller scale experiments can effectively inform predictions at larger scales, even when the datasets for the latter are sparse or incomplete. This capacity to generalize learning across scales represents a formidable advance, dramatically reducing the experimental burden traditionally associated with scaling reactions.

Focusing on a benchmark molecular reaction system with complexities typical of pharmaceutical synthesis, the researchers first constructed a detailed mechanistic model encapsulating known pathways, reaction kinetics, and physically relevant variables such as temperature, pressure, and solvent effects. They then supplemented this model with a deep neural network trained on extensive experimental data collected from small and medium-scale reactions. The neural network learns residual patterns and corrections beyond what the mechanistic equations can capture, effectively acting as an intelligent error-correcting layer.

The hybrid model was validated through rigorous comparison with purely mechanistic predictions and experimental data at multiple scales. Remarkably, the hybrid approach consistently outperformed classical models, delivering enhanced accuracy in predicting reaction yields, selectivities, and time-resolved concentration profiles. Such performance is not merely quantitative improvement; it translates directly to increased confidence in scaling decisions, reducing costly trial-and-error iterations common in process development.

One of the striking findings is how the model dynamically adjusts predictions to account for scale-dependent phenomena that are traditionally difficult to capture. For instance, variations in mixing efficiency, heat transfer limitations, and mass transport resistances—all of which often derail scale-up predictions—were implicitly learned by the transfer learning component. This ability to internalize and adjust for physical scaling effects without explicit parameterization is indicative of the power of combining mechanistic intuition with data-driven learning.

Furthermore, the transfer learning strategy exhibited robustness in adapting to process perturbations and changes in reaction conditions. This flexibility suggests practical applications not only in initial scale-up but also in continuous process optimization and adaptive control, where ongoing data streams can refine model predictions in near real-time. Such capabilities align closely with the emerging paradigm of Industry 4.0 and smart manufacturing.

An additional layer of sophistication comes from the mechanistic foundation of the model, which ensures interpretability and maintainability. Unlike black-box models that often lack scientific insight and can be brittle when pushed beyond their training boundaries, the hybrid framework retains explicit reaction pathways and physical constraints. This feature facilitates mechanistic understanding and provides a platform for hypothesis testing, offering researchers actionable insights into reaction mechanisms and opportunity spaces for improving reaction conditions.

The scalability of the approach was demonstrated across a wide range of molecular systems exhibiting different complexity levels, including catalytic cycles with multiple intermediates, competing side reactions, and sensitive stereochemical outcomes. These proof-of-concept demonstrations underscore the generalizability of the framework, increasing its appeal for deployment in varied chemical sectors such as fine chemicals, agrochemicals, and materials science.

Importantly, the research opens intriguing possibilities for integrating experimental design with computational prediction. By leveraging uncertainty quantification methods embedded in the hybrid model, future studies can intelligently prioritize experiments that maximize information gain, accelerating process understanding and optimization. This closed-loop paradigm, often referred to as self-driving labs, is a rapidly advancing frontier that could be fundamentally enabled by such hybrid mechanistic and machine learning models.

While the study represents a significant advancement, the authors acknowledge challenges ahead, including the need for extensive, high-quality experimental datasets to train the neural networks effectively, especially when extending to more complex multi-component systems. However, the transfer learning mechanism partially alleviates this hurdle by enabling knowledge reuse and reducing data requirements at later stages. Advances in high-throughput experimentation and in situ analytical techniques are likely to synergize well with this modeling approach, further expanding its applicability.

In conclusion, the hybrid mechanistic modeling coupled with deep transfer learning showcased by Chen et al. marks a watershed moment in molecular reaction scale-up science. This approach intelligently combines the strengths of physics-based and data-driven paradigms, overcoming longstanding scale-up challenges, and charting a path toward smarter, faster, and more reliable reaction engineering. As industries continue to seek sustainable and efficient manufacturing routes, tools such as this will be indispensable in bridging the gap between lab-scale discoveries and commercial-scale reality, ultimately accelerating innovation and reducing time-to-market for vital chemical products.

Subject of Research: Scale-up methodologies for complex molecular reaction systems using hybrid mechanistic modeling and deep transfer learning.

Article Title: Scale-up of complex molecular reaction system by hybrid mechanistic modeling and deep transfer learning.

Article References:

Chen, Z., Xie, Y., Xu, C. et al. Scale-up of complex molecular reaction system by hybrid mechanistic modeling and deep transfer learning. Nat Commun 16, 8905 (2025). https://doi.org/10.1038/s41467-025-63982-2

Image Credits: AI Generated

Tags: advanced techniques in chemical kineticsdeep transfer learning in chemistryenhancing precision in molecular synthesishybrid AI models for chemical reactionsinnovative approaches to reaction engineeringmechanistic modeling and AI integrationmultiphase systems in chemical engineeringnonlinear modeling of chemical processesovercoming challenges in reaction scalingpredictive methodologies in molecular engineeringscaling complex molecular reactionstransforming industrial chemical processes with AI